Spill Containment Equipment

Supplies To Ensure Potential Hazardous Spills Are Minimized

Additional Information

In order to reduce your risks to health and safety in your facility, proper spill containment equipment is an absolute must

No matter what industry you're in, exposure to potentially dangerous liquids and chemicals can cause serious harm to both property and people.

Read on to discover more about the importance of good spill containment and why this industrial equipment is so crucial to keep you and your assets safe.

The Benefits of Spill Containment

No matter what size your business is or what type of materials you work with, a good spill containment plan should always be in place. Even if this plan is not required by OSHA or other local laws, it's the best way to protect yourself and your workers from potential harm. Much like you'd use cable management to keep areas clear, containing spills reduces the probability of various injuries and health-related issues.

Using quality spill containment equipment will keep toxic elements from entering into the water supply or from seeping into the ground. It's not just good business sense for your company, but it's also a good method to start using in order to protect the environment.

A large spill containment unit can hold higher amounts of chemicals or liquids than small, disposable options. If you run a large facility and have high volumes of dangerous liquids, you'll need to choose containment equipment that can handle heavy volumes.

When you put this equipment in place, it can save you money in the long run. If a spill ever occurs, you, your building, and your workers will all be protected. It may also potentially prevent you from having to pay serious fines or penalties.

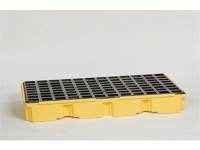

Whether it's the natural world outside or the inside of your place of business, you need a spill containment plan and equipment to reduce the risks of damage. Look for spill containment supplies that will keep your particular materials contained in a safe, legal manner. These supplies can range from holding tanks to drums, palettes, and even rugged utility trays.

Oil Containment Methods

If you work with any kind of oil, it's absolutely crucial to keep it properly contained. Oil runoff and spills can cause serious harm to the environment and can also create a dangerous workplace for your employees.

Specially designed palettes allow you to place oil drums directly on top while they catch any leaking fluids. You can also use heavy-duty industrial trays with high walls and place them directly underneath vehicles or any other equipment that uses oil.

If the oil happens to leak, this spill containment equipment will prevent it from spreading to the floor, leaking outside, or getting into the water supply. Look for spill containment berms that can corral any extra oil and keep it in one location.

A berm can be customized to almost any size so you can easily use it for a variety of equipment and industrial applications. The berm is an easy way to quickly stop a spill and contain oil or other chemicals and liquids as needed.

Companies who end up leaking oil into the waterways can face serious repercussions. The EPA and OSHA both have specific regulations in place that state how to keep oil and other chemicals contained in a safe manner. If you're ever in doubt, contact your local branch or visit their website for more information.

The term secondary containment refers to the use of preventative methods that keep oil and other dangerous liquids from getting into the soil and water. Use berms, drums, or containment palettes to ensure that any excess or leaking oil is caught before it starts to spread.

Spill Cleanup Methods and Equipment

On a smaller scale, your employees should practice proper methods for cleanup. When a spill is cleaned up quickly, it will help to prevent possible injuries and avoid any damage to your inventory and equipment.

Use absorbent materials like pads, pillows, or loose materials that can easily soak up any spilled liquids. You can also use biohazard kits if your facility uses or handles biohazardous materials. These kits will limit human exposure and help to prevent environmental damage.

For chemicals, use special neutralizers that counteract any potentially hazardous effects of spilled chemicals. The neutralizers will also reduce the risk of exposure during the cleanup process.

Of course, containment equipment like berms, booms, and drums are your best option, especially when dealing with liquid on a larger scale. These barriers will prevent dangerous liquids from spreading further. Use a leak diverter to redirect any leaks from pipes or the ceiling and have them go directly into your spill containment equipment.

Train your employees and educate them about the importance of having a good spill prevention plan. When you combine training with the right equipment, it will ensure a safer, more healthy workplace for everyone. Stay updated on the latest developments in spill containment so you're always informed of new products that will keep your facility safe.

Contain Spills with Quality Equipment

From oil and chemicals to biohazardous materials, it's crucial to have a spill containment plan and equipment in place. When you practice spill containment regularly, it's much easier to get peace of mind and to be sure that everything is under control.

Containing spilled materials in a safe manner is not just good for your company, but it's also much better for the environment. Follow the current laws and regulations to make sure that your facility is practicing the proper methods and using the right equipment for your specific industry.

Visit our website today for our current inventory of spill containment equipment and to view our catalog and find out more about our products.