Braided Cable Sleeving

Wide Range Of Sizes & Materials, General Use to Industrial Engineering

Additional Information

What are the different Types Of Braided Sleeving?

General-purpose braided sleeving is ideal for cable and wire management projects where easy application and durability are the main determinants of a successful solution. These options offer the most versatility due to the available expandable and side entry braided sleeving while maintaining the integrity necessary for durability and resistance to unwanted materials. Expandable sleeving expands to simplify the application process making the feeding of cables or wires through the sleeving as efficient as possible and then contracts to form to the bundle allowing for a clean and cohesive cable harness regardless of any inconsistencies in the width of wires or cables. For conditions that demand ease of use but require increased resistance to abrasion, tight weave options are available as well. Side-entry sleeving is generally utilized in circumstances where the disconnection of wires or hoses is impossible. Wrap-around braided sleeving is especially helpful during these installation or reapplication processes.

Heavy Duty Sleeving offers the resilient integrity required to withstand the most rigorous conditions. These sleeving options are highly cut, abrasion, and temperature resistant and will not burn, melt, or support combustion. They are also able to boast these qualities while maintaining the pliability necessary to protect the most vulnerable components from the harshest environments. Heavy-duty sleeving can resist acids, bases, solvents, fuels, and salt from compromising hose functions as well as being able to deflect or contain hose ruptures.

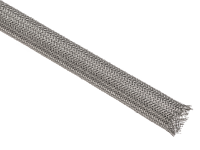

Braided Metal Sleeving offers cut and abrasion-resistant options that are ideal for a wide variety of uses, including grounding solutions, high-intensity weather, and temperature resistance. Metal sleeving is exceptionally durable and has EFI, RFI, ESD, and UV resistant options as well as antimicrobial and germicidal options. They are uniquely functional, flexible, durable, and aesthetically pleasing, making them perfect for many automotive, aerospace, and outdoor applications. For the most demanding applications, we recommend using virtually indestructible options like braided stainless steel sleeves; even your most exposed wires, cables, and hoses will be safely tucked away while your project remains aesthetically stunning and rust-free.

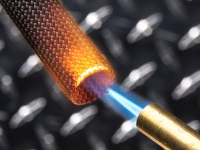

Flame retardant sleeving options offer the same durability and easy application of general-purpose braided sleeving solutions with the added benefit of fire prevention. These sleeving options are optimal for engineering, automotive, electrical, and other industrial circumstances where fire damage is a potential concern. Flame retardant sleeving will protect cables, wires, and hoses from flames as well as help to reduce the spreading of fire until the fire can be fully extinguished, potentially saving other essential components.

Technical Engineering Sleeving options offer the most technologically advanced materials which allow them to offer qualities that meet the most demanding specifications while remaining incredibly lightweight and pliable. Many of these sleeving options offer peak chemical, temperature, abrasion, and moisture resistance as well as other valuable qualities like industry-leading ease of application and resistance to bacterial growth.

As the name would suggest, high-temperature sleeving options are the most resistant to extreme temperatures. The ability of high-temperature sleeving to withstand both extremely high and low temperatures combined with its ability to resist common chemicals and solvents, as well as its easy and fast installation, make it ideal for many engineering, aerospace, and automotive uses. The fiberglass and silica composition used in the high-temperature options will keep your cables, wires, and hoses cool, calm, and collected at temperatures approaching 2000 degrees Fahrenheit.

Specialty Sleeving options can accommodate the most specific braided sleeving needs. Specialty sleeving includes options that are easily edited out of video production, noise reducing, up to 1500 times more reflective than bright white, and sleeving thin enough to be conducive to micro-optics. Specialty options allow you to protect cables, wires, and hoses from vulnerability without inconveniencing the major project at hand.

Automotive sleeving options offer extreme abrasion and temperature resistance necessary for resilience in high-performance automotive conditions. These sleeving options will accommodate any quality you may need in a sleeving solution, whether that be extreme temperature or abrasion resistance, non-conductivity, penetration protection, or noise reduction. Regardless of the automotive project at hand, Cable Ties and More has a braided sleeving solution that will allow all hoses, wires, and cables to perform at the high standard required of them.

Cable Ties and More offers all the tools and accessories necessary to ensure your braided sleeving is cut perfectly and applied seamlessly to take full advantage of the protective qualities of the sleeving. Whether your braided sleeving requires a hot knife to ensure a seamless cut or Kevlar sheers to penetrate the most resilient of material we have you covered.