Heat Shrink Tubing

2:1 / 3:1 / 4:1 Shrink Ratios Single & Dual Wall, Variety Of Materials

Additional Information

Heat shrink can be found in an array of materials that suit virtually any application. It has several useful applications, including providing electrical insulation for wires, splices, terminals, joints, connections, and bundling loose items including wires and used as a protective covering.

What is Heat Shrink Tubing and How is it Commonly Used?

The innovation and creativity of people across the globe has led to an array of amazing inventions that you probably can’t imagine life without. For example the air conditioner, laundry detergent, and even zippers.

Another invaluable invention is heat shrink tubing. Have you ever used this impressive item? If not, you need to.

Not only is it pretty cool in how it works, but it’s also an invaluable tool to have on-hand. Keep reading to learn more about our bulk heat shrink tubing options and applications.

The History of Heat Shrink Tubing

Heat shrink tubing hit the market in the 1950s. It was created by the Raychem Corporations engineer founder Paul Cook. He made use of radiation chemistry (which is what the company is named for) to create the two main products the company is best known for:

- Heat shrinkable tubing

- Lightweight aircraft cable

Even though Raychem was the company that created the original heat shrink polymers, today, an array of manufacturers sell them.

Since it was developed in the 50s, electrical shrink tubing has become highly sought after for the insulating properties and commonly used for electrical related projects.

How is Heat Shrink Tubing Used?

Some of the specific ways you can use heat shrink tubing include:

- Provide electrical insulation (wire repairs, splices, covering terminals, other connectors, etc.)

- Identify components (via custom color, printing, etc.)

- Bundle loose items (usually wire harnesses and wires)

- Change the surface finish of something

- Color-coding

- Thermal insulation

- Strain relief

- Environmental seal to protect from chemicals and moisture

- A protective covering that safeguards from denting, scuffing, peeling, chipping, cutting, abrasion, and low impacts

As you can see, the uses for heat shrink tubing are vast.

What is Used to Make Heat Shrink Tubing?

Today’s heat shrink tubing is made of several different thermoplastics. The most commonly used include:

- Kynar

- Fluorinated ethylene propylene

- Polytetrafluoroethylene

- Neoprene

- Viton (for corrosive or high-temp environments)

- Polyvinyl chloride

- Polyolefin

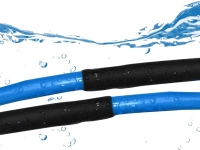

Along with these polymers, some special-application heat shrink also includes an adhesive lining that assists in bonding the tubing to the underlying connectors and cables. This creates strong seals that are often waterproof.

Another material often added to some types of heat shrink tubing is a thick, conductive polymer film. This offers an electrical connection between the conductive objects being connected. With this method, no soldering is necessary.

Learn more about some of the most common materials used here.

Polyolefin Heat Shrink vs. PVC Heat Shrink

As mentioned above, polyolefin is the most common material used for heat shrink tubing. The advantages offered by this include the cross-linking of the polymer chains. This allows it to withstand higher temperatures.

However, there are some people who have the misconception that all heat shrink is the same. This means it doesn’t matter what is purchased.

Even though PVC can’t withstand the highest temperatures like polyolefin, there are some advantages offered by PVC. The most important of which is that it is more affordable. Usually, you can find PVC for a fraction of what polyolefin costs.

If your needs for heat shrink tubing involve an environment where the continuous high temperature is under 105 degrees Celsius, you should consider using PVC. Along with the more affordable prices offered by PVC, it also provides you with colors that are more vibrant than polyolefin and better clarity.

There are two other advantages offered by using PVC instead of polyolefin. This includes the fact that PVC is a flame-retardant material, and polyolefin isn’t. Also, PVC is much more durable than polyolefin. It offers better abrasion resistance and tensile strength.

Why Does Heat Shrink Tubing Shrink?

Most plastics you encounter won’t shrink down if they are heated up. As a result, there’s got to be something that makes heat shrink tubing do this.

This is caused by cross-linking, which is the process of exposing the polymer to radiation. By doing this, covalent bonds form between the atoms of the polymer.

After WWII, scientists discovered radiation could be used to alter the molecular structure of some plastics. This didn’t cause the plastic to melt or develop a flowing consistency, regardless of the temperatures present.

Covalent bonds also provide plastic memory. This means that after the polymer has been stretched and cross-linked in an expanded shape, it’s going to automatically shrink back to the original dimensions when the proper amount of heat is applied to it.

Tips for Selecting the Right Type of Heat Shrink Tubing for Your Needs

As seen in the information above, there’s an array of heat shrink tubing materials available. Usually, general-purpose materials will cover most needs.

The most popular material used is a polyolefin. It’s able to be used unless the requirements have special considerations. Some things to keep in mind when choosing heat shrink tubing are found here.

Heat Shrink Ratios?

A higher shrink ratio is going to let the sleeve fit over bigger objects, such as connectors. Once in place, the tubing is shrunk to the smaller diameter of the cable. However, a general rule of thumb is to never use a higher ratio than the application demands.

Common ratios for heat shrink tubing include:

2:1 Shrink Ratio

The tube will become half of the original size when any heat is applied. You can also look at this ratio as the original size of the tube is twice as large as the shrunken form.

3:1 Shrink Ratio

With a three to one ratio, the tube will become a third of the original size when heat is applied. This means that the original size is three times larger than the shrunken form.

4:1 Shrink Ratio

With this size, the tube will be a quarter of the original size when the proper amount of heat is applied. It also means the original size is four times bigger than when it is shrunk.

The Sleeve Diameter

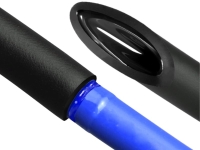

It’s important to use a heat shrink tubing that has a final shrink diameter that’s smaller than the item the sleeve is put on. Put simply, you don’t want to completely shrink the sleeve. The sleeve should fit tightly against the object, which is something that’s not possible if the object is smaller than the final shrink diameter.

The Wall Thickness

The modern heat shrink sleeves are available in several thicknesses. Thicker walls provide better rigidity, abrasion resistance, and the ability to stand up to wear and tear.

If you don’t need this additional protection or robustness, a thinner sleeve wall is adequate.

The Stiffness

Each sleeve available has a different degree of flexibility. Sleeves that are more rigid are a good choice to achieve strain relief for terminals or connectors. Here, reducing flexing is a goal of the heat shrink tubing.

Sealing Ability

When properly applied, heat shrink tubing will seal the interface between the tubing and an object. If sealing is an important factor, select a material that can withstand various contaminants.

Some tubing includes a meltable or adhesive inner layer for applications that demand superior sealing levels. In most situations, standard tubing will provide plenty of sealing, but the adhesive lined tubing takes this a step further.

Shrink Temperature

Most polyolefin materials have a recommended shrink temperature of around 90 degrees Celsius. However, other materials have shrink temperatures up to 250 degrees Celsius, like Teflon.

Heating Methods

The most common way to shrink heat shrink tubing onto something is by using a small, hand-held heat gun. However, if you have higher volumes, the preferred method for shrinking the tubing is a flow-through oven.

This method will help ensure complete recovery of your tubing since it is evenly exposed to sufficient heat for an adequate amount of time.

Another method that some people use is focused light. This is emitted by halogen bulbs and once the needed temperature is achieved, the tubing shrinks.

Heat Shrink Tubing and Its Many Applications

When you think about it, heat shrink tubing is a unique and extremely useful invention. Think about all the things you couldn’t do if it did not exist.

If you have a project that demands high quality, low-cost heat shrink tubing, contact us. We have a huge selection of products that will exceed your expectations.

You’ll also find our online store offers solutions for all your wire management needs. With 14 years of experience, you can feel confident we have the wiring, heat shrink tubing, and other solutions you need.

Heat Shrink Tubing

Heat shrink tubing is a type of protective electrical insulation tubing that activates and shrinks when the heat is applied. Shrink tube is most commonly used in the insulation protection of cables, wires, joints, and terminals due to its durable exterior and tight fit. Heat shrinkable tubing is preferred to other electrical insulation tubing due to heat shrink's ability to mold around the shape of the cable or wire connection point. Therefore, protecting against various environmental strains and abrasions. While all types of heat shrink tubing generally serve the same function, different needs require different shrinkable tubing. Due to the vast array of cable and hose diameters, heat shrink is produced in various sizes, thicknesses, and materials. Depending on the desired use, and it is helpful to understand which shrink tubing materials are best for your particular needs. Cabletiesandmore boasts the largest Online selection of heat shrink tubing for sale. We provide a wide variety of heat shrink tubing that is in stock, depending on your specific situation.

What kind of heat shrink tubing should I buy?

The first feature to think about is the size. How big are the wires, cables, or general devices you wish to use with shrink tubing? 2:1 heat shrink tubing shrinks to half of its original size. 3:1 heat shrink tubing will shrink to a ratio of one-third of its original size, and 4:1 heat shrink tubing will shrink to one-quarter of its original size. You will want to pick a sizeable heat shrink diameter that is bigger than your largest measurement but will shrink to fit your smallest measurement snugly.

Next, you will want to determine the best material for your heat shrink tubing. As mentioned, different shrink sleeves are needed for different circumstances. When deciding what heat shrink to use for an industrial application, you may choose to use our 2:1 High Temp Viton Heat Shrink Tubing or diesel resistant heat shrink due to their powerful chemical resistance.

2:1 Polyolefin Heat Shrink is the standard for heat shrink tubing material because of its overall temperature and chemical resistance, commonly used for cable management when bundling and insulating of wires. For protection against moisture, dual wall adhesive lined heat shrink sleeving provides a water-proof seal. Alternatively, fabric heat shrink sleeving uses a unique blend of Polyolefin and Polyester yarns to resist trapping water and humidity. Kynar heat shrink tubing provides the ultimate heat resistance and flexibility, making it ideal for small spaces like fuse coverings. Neoprene heat shrink is a popular choice for military and aerospace applications because neoprene is flame-retardant and is also highly resistant to lubricating oils and hydraulic fluids. However, diesel resistant heat shrink tubing is also a suitable choice. We also provide different colors of heat shrink tubing for identification purposes, as well as customizable heat shrink tubes if you would like specific lettering or wording.

Other Things to Know Before You Buy heat shrink tubing?

Ensure that heat shrink tubing is applicable for your intended use. variable temp heat guns and butane torches are efficient and effective, providing the maximum heat necessary for proper shrinkage. You will likely want to find one that is handheld and easy to use, but make sure to use the appropriate temperature range depending on your shrink tubing. Remember, different materials can withstand different heat levels!

Alternatively, you may be interested in using

adhesive-lined heat shrink wrap tape instead. Some applications may not be able to fit through shrink tubing, making heat shrink tape a better choice. It provides the necessary bonding and protection with added flexibility and versatility. Here at cable ties and more, we carry a wide selection of heat shrink tubing and heat shrink accessories for your unique needs

How to install heat shrink tubing?

Before installing heat shrink tubing, you should educate yourself on how to shrink heat shrink. There are more than a few ways that heat shrink tubing can be shrunk to its recovered size. However, to properly install heat shrink begins by feeding the cable or hose inside the opening of the heat shrink either by hand or using an electrical wire fish rod to get the tubing to the end of the run. Once the heat shrink fully encloses the wire or hose, you can start applying high heat from Heat tools. Finally, sit back and watch as the shrink tube recovers down to a snug fit on the cable or hose that is now insulated internally.