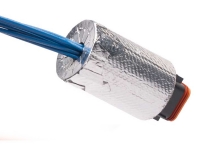

Techflex® Weld Wrap High Temp Braided Sleeving

Heavy Duty Acrylic Coated Fiberglass With Hook & Loop Closure

0.0 / 5

Weld Wrap Sleeving Features

- Acrylic Coated Fiberglass

- Extremely Abrasion and Cut Resistant

- Will Not Burn or Support Combustion

- Resists Common Chemicals & Solvents

- Easy to Install

- Easy Hook and Loop Wraparound Installation

- Continuous Temperature Range: -40° to 400°F (-40° to 204 °C.)

- Intermittent Exposure: 1000°F / 538°C

Note: Measurements are listed as inside diameter.

Weld Wrap sleeving is constructed from braided fiberglass yarns with high temperature coating and hook and loop closure. Commonly used for protecting welding hoses from molten splatter and abrasion from moving and dragging. This product will withstand continuous exposure to temperatures of 400°F, and intermittent exposure to temperatures of 750°F. The heavy duty hook and loop closure ensures a tight seal, and allows Weld-Wrap to be installed easily over existing assemblies. Weld-Wrap also provides a high level of abrasion and penetration protection to increase the useful life of any hoses exposed to rough or abrasive surfaces.

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Wall Thickness | Velcro Width | Standard Spool Put-Ups | Available Colors | Lbs/ 100' | |

| Bulk | Shop | ||||||

| 1" 1 1/2" 2" 2 3/8" 2 3/4" 3" 3 1/4" 3 1/2" 4" | WWN1.00BK WWN1.50BK WWN2.00BK WWN2.38BK WWN2.75BK WWN3.00BK WWN3.25BK WWN3.50BK WWN4.00BK | .04" .04" .04" .04" .04" .04" .04" .04" .04" | 0.84" 0.84" 1.55" 1.55" 1.55" 1.55" 1.55" 1.55" 1.55" | 150' 150' 150' 150' 150' 150' 150' 150' 150' | 50' 50' 50' 50' 50' 50' 50' 50' 50' | BK BK BK BK BK BK BK BK BK | 8.4 11.0 13.8 14.8 16.4 18.4 19.2 20.4 21.7 |

| Physical Properties | |

| Monofilament Thickness (ASTM D-204) | NA |

| Flammability Rating | Non-Flammable |

| Recommended Cutting | Scissor/Shears |

| Colors | 1 |

| Wall Thickness | .04 |

| Abrasion Resistance | High |

| Moisture Absroption % | .01 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Aromatic Solvents | 1 |

| Alipahtic Solvents | 1 |

| Chlorinated Solvents | 1 |

| Weak Bases | 1 |

| Strong Bases | 1 |

| Salt Water (O-S-1926) | 1 |

| Hydraulic Fluid (MIL-H-5606) | 1 |

| Lubricating Oil (MIL-A-8243) | 1 |

| De-Icing Fluid (MIL-A-8243) | 1 |

| Strong Acids | 2 |

| Strong Oxidants | 2 |

| Esters/Ketones | 1 |

| UV Light | 1 |

| Petroleum | 1 |

| Fungus (ASTM G-21) | 1 |

| Salts | 1 |

| Operating Temperatures | |

| Minimum Continuous | -40°F/-40°C |

| Maximum Continuous (MIL-I-23053) | 400°F/204°C |

| Other Information | |

| UL/CSA | No |

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

Weld Wrap sleeving is constructed from braided fiberglass yarns with high temperature coating and hook and loop closure. Commonly used for protecting welding hoses from molten splatter and abrasion from moving and dragging. This product will withstand continuous exposure to temperatures of 400°F, and intermittent exposure to temperatures of 750°F. The heavy duty hook and loop closure ensures a tight seal, and allows Weld-Wrap to be installed easily over existing assemblies. Weld-Wrap also provides a high level of abrasion and penetration protection to increase the useful life of any hoses exposed to rough or abrasive surfaces.

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Wall Thickness | Velcro Width | Standard Spool Put-Ups | Available Colors | Lbs/ 100' | |

| Bulk | Shop | ||||||

| 1" 1 1/2" 2" 2 3/8" 2 3/4" 3" 3 1/4" 3 1/2" 4" | WWN1.00BK WWN1.50BK WWN2.00BK WWN2.38BK WWN2.75BK WWN3.00BK WWN3.25BK WWN3.50BK WWN4.00BK | .04" .04" .04" .04" .04" .04" .04" .04" .04" | 0.84" 0.84" 1.55" 1.55" 1.55" 1.55" 1.55" 1.55" 1.55" | 150' 150' 150' 150' 150' 150' 150' 150' 150' | 50' 50' 50' 50' 50' 50' 50' 50' 50' | BK BK BK BK BK BK BK BK BK | 8.4 11.0 13.8 14.8 16.4 18.4 19.2 20.4 21.7 |

| Physical Properties | |

| Monofilament Thickness (ASTM D-204) | NA |

| Flammability Rating | Non-Flammable |

| Recommended Cutting | Scissor/Shears |

| Colors | 1 |

| Wall Thickness | .04 |

| Abrasion Resistance | High |

| Moisture Absroption % | .01 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Aromatic Solvents | 1 |

| Alipahtic Solvents | 1 |

| Chlorinated Solvents | 1 |

| Weak Bases | 1 |

| Strong Bases | 1 |

| Salt Water (O-S-1926) | 1 |

| Hydraulic Fluid (MIL-H-5606) | 1 |

| Lubricating Oil (MIL-A-8243) | 1 |

| De-Icing Fluid (MIL-A-8243) | 1 |

| Strong Acids | 2 |

| Strong Oxidants | 2 |

| Esters/Ketones | 1 |

| UV Light | 1 |

| Petroleum | 1 |

| Fungus (ASTM G-21) | 1 |

| Salts | 1 |

| Operating Temperatures | |

| Minimum Continuous | -40°F/-40°C |

| Maximum Continuous (MIL-I-23053) | 400°F/204°C |

| Other Information | |

| UL/CSA | No |

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.