Techflex® Braided Carbon Fiber Sleeving

Stronger & Lighter Than Virtually Any Other Sleeving Material Types

0.0 / 5

Carbon Fiber Braided Sleeving Features

- Max continuous Operating temperature of 419 ºF

- Lighter Than Virtually All Other Sleeving

- Ideal for Strong Lightweight Tubular Structures

- Perfect When You Need Coverage, Strength & Can't Afford to Add Much Weight

- Cuts Easily with Scissors

- Insulates Delicate Wires & Components

- Made From Polyacrylonitrile (PAN)

- Non-Flammable

- UV Resistant

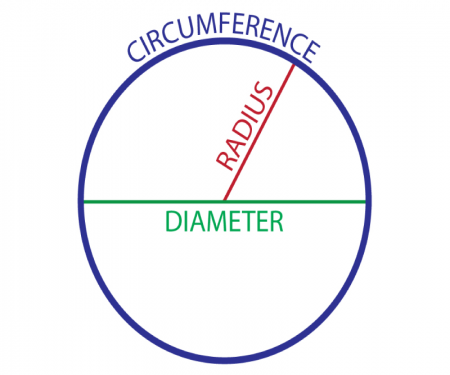

Inside Diameters Are Measured as Round Not Flat

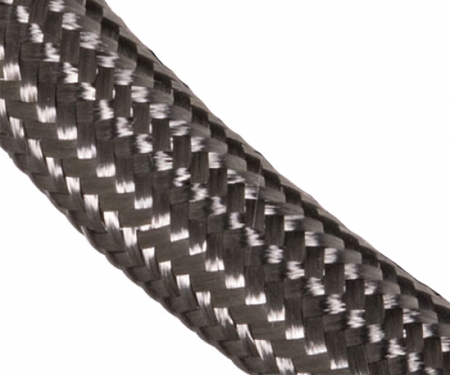

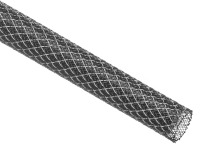

Carbon fiber braided sleeving provides a strong, biaxial carbon fiber matrix for stiff, lightweight tubular structures up to 3” in diameter without seams or overlap. The tightly braided thick flexible sleeving will form itself to accommodate elliptical or asymmetrical profiles and provide the full coverage required for radial stability and torsional strength. Fabricators know that resin-coated carbon fiber structures are stronger and lighter than virtually any other construction types. Carbon Fiber construction techniques are appearing in everything from state of the art military and aerospace airframes to hockey sticks, fishing rods and model cars. Carbon Fiber constructions can be cut, drilled, sanded and tooled with commonly available power or hand tools. Carbon Fiber Biaxial sleeves can be painted or left with the braid structure exposed.

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Wall Thick | Expansion Range | Standard Spool Put-Ups | Lbs/ 100' | ||

| Min. | Max. | Bulk | Shop | ||||

| CARBON LIGHT | |||||||

| 1/4" 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" | CAL0.25 CAL0.50 CAL0.75 CAL1.00 CAL1.25 CAL1.50 CAL2.00 | .013" .013" .013" .013" .013" .013" .013" | 1/8" 1/4" 5/16" 3/8" 1/2" 5/8" 3/4" | 5/16" 5/8" 7/8" 1 1/16" 1 1/2" 1 3/4" 2 3/16" | 500' 250' 250' 200' 125' 100' 100' | 100' 50' 50' 50' 25' 25' 25' | 0.38 0.75 1.21 1.51 1.81 2.26 2.72 |

| Physical Properties | |

| Recommended Cutting | Scissor |

| Colors | 1 |

| Wall Thickness | .013 - .030 |

| Abrasion Resistance | Medium |

| Specific Gravity | 1.75 - 1.85 |

| Hard Vacuum Data (ASTM E-595 at 10-5 torr) | |

| TML | .19 |

| CVCM | .00 |

| WVR | .14 |

| Outgassing | Medium |

| Oxygen Index (ASTM D-2863) | 21 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Esters/Ketones | 1 |

| UV Light | 1 |

| Other Information | |

| UL/CSA | No |

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

Carbon fiber braided sleeving provides a strong, biaxial carbon fiber matrix for stiff, lightweight tubular structures up to 3” in diameter without seams or overlap. The tightly braided thick flexible sleeving will form itself to accommodate elliptical or asymmetrical profiles and provide the full coverage required for radial stability and torsional strength. Fabricators know that resin-coated carbon fiber structures are stronger and lighter than virtually any other construction types. Carbon Fiber construction techniques are appearing in everything from state of the art military and aerospace airframes to hockey sticks, fishing rods and model cars. Carbon Fiber constructions can be cut, drilled, sanded and tooled with commonly available power or hand tools. Carbon Fiber Biaxial sleeves can be painted or left with the braid structure exposed.

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Wall Thick | Expansion Range | Standard Spool Put-Ups | Lbs/ 100' | ||

| Min. | Max. | Bulk | Shop | ||||

| CARBON LIGHT | |||||||

| 1/4" 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" | CAL0.25 CAL0.50 CAL0.75 CAL1.00 CAL1.25 CAL1.50 CAL2.00 | .013" .013" .013" .013" .013" .013" .013" | 1/8" 1/4" 5/16" 3/8" 1/2" 5/8" 3/4" | 5/16" 5/8" 7/8" 1 1/16" 1 1/2" 1 3/4" 2 3/16" | 500' 250' 250' 200' 125' 100' 100' | 100' 50' 50' 50' 25' 25' 25' | 0.38 0.75 1.21 1.51 1.81 2.26 2.72 |

| Physical Properties | |

| Recommended Cutting | Scissor |

| Colors | 1 |

| Wall Thickness | .013 - .030 |

| Abrasion Resistance | Medium |

| Specific Gravity | 1.75 - 1.85 |

| Hard Vacuum Data (ASTM E-595 at 10-5 torr) | |

| TML | .19 |

| CVCM | .00 |

| WVR | .14 |

| Outgassing | Medium |

| Oxygen Index (ASTM D-2863) | 21 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Esters/Ketones | 1 |

| UV Light | 1 |

| Other Information | |

| UL/CSA | No |

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.