Techflex® Flexo® 6 mil Braided Cable Sleeving

High Density Fine Thread Sleeving - Can Be Used For Filtration

0.0 / 5

Flexo 6 Mil Sleeving Features

- Ultra Thin for Specialized Fiber Applications

- Economical, Long Lasting Filtration Solutions

- Recommended Cutting with Hot knife

- Operating Temperature Range: -94° to 257°F (-70° to 125°C.)

- Easy to Engineer to Unique Specifications

- Reduced Wall Thickness

- 482°F / 250°C. Melt Temp.

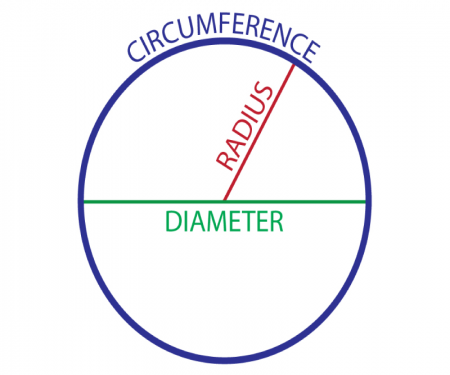

Inside Diameters Are Measured as Round Not Flat

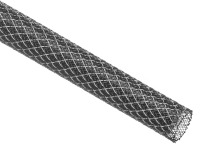

One of the most unique applications for expandable braided sleeving is the filtration of small particles from flowing liquids. Our Flexo 6 Mil is a great off the shelf solution. Flexo 6 Mil uses chemical resistant PET fiber to create an ultra flexible sleeve. The small monofilaments bond easily when heated to create lasting shapes, or with one end sealed completely, a durable filtration sock. Flexo 6 Mil is densely braided to provide extraordinary filtration and can easily be backflushed for cleaning without losing its shape or properties.

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Expansion Range | Standard Spool Put-Ups | Colors | Lbs/ 100' | ||

| Min. | Max. | Bulk Spool | Shop Spool | ||||

| 1/8" 1/4" 5/16" 3/8" 1/2" 5/8" | FFN0.13CL FFN0.25CL FFN0.31CL FFN0.38CL FFN0.50CL FFN0.63CL | 1/16" 3/16" 5/16" 5/16" 1/2" 1/2" | 1/2" 3/8" 7/16" 5/8" 3/4" 1" | 1,000' 1,000' 500' 500' 500' 250' | 225' 200' 150' 125' 100' 100' | CL CL CL CL CL CL | 0.18 0.33 0.43 0.53 0.82 1.00 |

| Physical Properties | |

| Monofilament Thickness (ASTM D-204) | .006 |

| Flammability Rating | N/A |

| Recommended Cutting | Hot Knife |

| Colors | 1 |

| Wall Thickness | .013 |

| Tensile Strength - Yarn (ASTM D-2265) lbs. | N/A |

| Abrasion Resistance | Medium |

| Specific Gravity | 1.3 |

| Moisture Absorption % (ASTM D-570) | .1 - .2 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Aromatic Solvents | 2 |

| Alipahtic Solvents | 1 |

| Chlorinated Solvents | 3 |

| Weak Bases | 1 |

| Strong Bases | 3 |

| Salt Water (O-S-1926) | 1 |

| Hydraulic Fluid (MIL-H-5606) | 1 |

| Lubricating Oil (MIL-A-8243) | 1 |

| De-Icing Fluid (MIL-A-8243) | 1 |

| Strong Acids | 3 |

| Strong Oxidants | 2 |

| Esters/Ketones | 1 |

| UV Light | 1 |

| Petroleum | 1 |

| Fungus (ASTM G-21) | 1 |

| Salts | 1 |

| Hard Vacuum Data (ASTM E-595 at 10-5 torr) | |

| TML | .19 |

| CVCM | .00 |

| WVR | .14 |

| Smoke D-Max (ASTM E-662) | N/A |

| Outgassing | Medium |

| Oxygen Index (ASTM D-2863) | 21 |

| Operating Temperatures | |

| Minimum Continuous | -94°F/-70°C |

| Maximum Continuous (MIL-I-23053) | 257°F/125°C |

| Melt (ASTM D-2117) | 482°F/250°C |

| Other Information | |

| Halogen Free | N/A |

| RoHS | Yes |

| UL/CSA | No |

| SVHC | None |

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

One of the most unique applications for expandable braided sleeving is the filtration of small particles from flowing liquids. Our Flexo 6 Mil is a great off the shelf solution. Flexo 6 Mil uses chemical resistant PET fiber to create an ultra flexible sleeve. The small monofilaments bond easily when heated to create lasting shapes, or with one end sealed completely, a durable filtration sock. Flexo 6 Mil is densely braided to provide extraordinary filtration and can easily be backflushed for cleaning without losing its shape or properties.

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| Nominal Size | Product Part # | Expansion Range | Standard Spool Put-Ups | Colors | Lbs/ 100' | ||

| Min. | Max. | Bulk Spool | Shop Spool | ||||

| 1/8" 1/4" 5/16" 3/8" 1/2" 5/8" | FFN0.13CL FFN0.25CL FFN0.31CL FFN0.38CL FFN0.50CL FFN0.63CL | 1/16" 3/16" 5/16" 5/16" 1/2" 1/2" | 1/2" 3/8" 7/16" 5/8" 3/4" 1" | 1,000' 1,000' 500' 500' 500' 250' | 225' 200' 150' 125' 100' 100' | CL CL CL CL CL CL | 0.18 0.33 0.43 0.53 0.82 1.00 |

| Physical Properties | |

| Monofilament Thickness (ASTM D-204) | .006 |

| Flammability Rating | N/A |

| Recommended Cutting | Hot Knife |

| Colors | 1 |

| Wall Thickness | .013 |

| Tensile Strength - Yarn (ASTM D-2265) lbs. | N/A |

| Abrasion Resistance | Medium |

| Specific Gravity | 1.3 |

| Moisture Absorption % (ASTM D-570) | .1 - .2 |

| Chemical Resistance 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected | |

| Aromatic Solvents | 2 |

| Alipahtic Solvents | 1 |

| Chlorinated Solvents | 3 |

| Weak Bases | 1 |

| Strong Bases | 3 |

| Salt Water (O-S-1926) | 1 |

| Hydraulic Fluid (MIL-H-5606) | 1 |

| Lubricating Oil (MIL-A-8243) | 1 |

| De-Icing Fluid (MIL-A-8243) | 1 |

| Strong Acids | 3 |

| Strong Oxidants | 2 |

| Esters/Ketones | 1 |

| UV Light | 1 |

| Petroleum | 1 |

| Fungus (ASTM G-21) | 1 |

| Salts | 1 |

| Hard Vacuum Data (ASTM E-595 at 10-5 torr) | |

| TML | .19 |

| CVCM | .00 |

| WVR | .14 |

| Smoke D-Max (ASTM E-662) | N/A |

| Outgassing | Medium |

| Oxygen Index (ASTM D-2863) | 21 |

| Operating Temperatures | |

| Minimum Continuous | -94°F/-70°C |

| Maximum Continuous (MIL-I-23053) | 257°F/125°C |

| Melt (ASTM D-2117) | 482°F/250°C |

| Other Information | |

| Halogen Free | N/A |

| RoHS | Yes |

| UL/CSA | No |

| SVHC | None |

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.