Linebacker®

Selection of Drop-Over & Heavy Duty Multi-Channel Cable Protectors

The Linebacker line of industrial cord protectors from Checkers provides a variety of solutions to protect cables and those who find their feet near them. From the FastLane drop over to the heavy-duty linebacker cable protectors line, their offerings will keep your cords covered and protected in the home, office, warehouse, school, construction site, event venue, or anywhere that needs a low profile protector that prevents tripping hazards.

Additional Information

Linebacker Cable Protectors (T-Connectors)

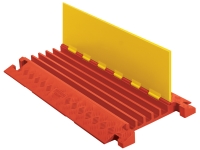

Linebacker cable protectors offer a reliable solution for shielding cables and wires from traffic or providing a smooth and skid-free surface to pedestrians and light-weight vehicle traffic. Linebacker cable protectors are also used in the industrial areas for securing cable cords and hoses.

We offer two varieties in linebacker cable protectors, including heavy duty linebacker cord cover with lid and open-top/drop over protectors. Both varieties are manufactured with polyurethane and supported with fiberglass installation for reducing the chances of damage or breakage. The heavy duty linebacker cord cover with lid is rectangular in shape. Its low height makes it a suitable choice for heavy pedestrian traffic and low to average vehicle traffic areas.

Vehicles travelling under 30 km/hr do not experience a bump with these cable protectors. However, vehicles going above this speed may experience minor bump. To warn traffic of upcoming bumps, signage boards should be placed at least 200 feet before the heavy duty linebacker cable protector.

Why You Should Use Linebacker Cable Protectors?

We offer a wide variety of linebacker cable protectors which can host different quantities of cables or hoses. The weather resistant polyurethane construction reduces the need for repair and maintenance. These are also corrosion and abrasion-resistant and are UV stabilized. All our linebacker cable protectors comply with OSHA, RoHS, REACH, and NEC requirements.

Extended Benefits

At Crowd Safety Products, we offer a range of linebacker cable protectors to meet different safety requirements. We offer turns and end caps for proper installation and finishing of the ends. The hinged lids enable you to extend the heavy duty linebacker cable protectors by attaching other cable covers with it. Constructed as light-weight units, these linebacker cable protectors can be easily transported from one place to the other. All our linebacker cable protectors are manufactured in the US to ensure quality manufacturing.

Operating Temperature–Each linebacker cable cover is temperature treated, which maximizes its temperature resistance. The linebacker cord cover can withstand temperatures ranging from -40° F to 120° F.

Hinge Pin Material – The hinge pin is constructed with reinforced fiberglass which is unbreakable and resistant to corrosion and abrasion.

Construction Material–All linebacker cable protectors are manufactured with UV-stabilized polyurethane.

Load Capacity–The load bearing capacity of linebacker cable protectors depends on the construction style and number of channels. The 5-channel and 4-channel linebacker cord cover can withstand 20,150 lbs per tire and 40,300 lbs per axle load. The 3-channel linebacker cord cover can withstand 14,210 lbs per tire and 28,420 lbs per axle load, whereas the 2-channel linebacker cord cover can withstand 10,880 lbs per tire and 21,760 lbs per axle load.

Applications and Areas of Use

- Industrial sites

- Festivals

- Convention centers

- Arenas

- Exhibition halls

- Amphitheaters

- Race tracks

- Roads and highways

- Fairs and amusement parks

- Outdoor sports events

- Music studios, dance halls and performance centers

- Construction sites

Installation Guidance

The positioning, placement and installation process depends on the size and load bearing capacity of the linebacker cable protectors.

- Thoroughly clean the area of placement and make sure that there are no bumps on the surface. It is important to ensure that the surface is smooth and even to avoid accumulation of hazardous liquids under the cable covers.

- Position the cable cover on the marked area and fix it on the ground. Next, put the female sides on top of the male sides and push them down to reach the connecting ends.

- Fix the lid cover.

- Insert the cable or hoses, putting only one cable/hose in each channel.

- Secure the lid cover with grip tape.