Makerbot® Method X 3D Printer

Designed to Handle the Most Complex 3D Printing Needs

0.0 / 5

Makerbot® Method X 3D Printer Features

- Dual performance extruders

- Dry-sealed material bays

- 100°C circulated heated build chamber

- Wifi Connectivity and 21 on-board sensors

- Remote monitoring and printing

- 25 Compatible CAD file types

- 5" Full-color capacitive touch screen

- Over 300,000 hours of reliability testing

A MANUFACTURING WORKSTATION

The MakerBot METHOD X is a high performance, tinker-free 3D printer designed to handle the most complex 3D printing needs. Featuring a 100°C heated chamber, the METHOD X prints a wide range of complex and durable ABS parts and other material types. Delivering uncompromised performance right out-of-the-box, the METHOD prints 2x faster than leading desktop printers and offers a seamless CAD to Part workflow.

Developed from the ground up leveraging industry-leading Stratasys® patents, Method features high quality components like a heated build chamber, precision dissolvable supports, and dry-sealed material bays. Perfect for manufacturing tools, end-user parts and functional prototypes. The Method X delivers maximum innovation with minimal investment.

Why MakerBot METHOD X?

aster and more precise printing than ever before with manufacturing features you need: Production-grade ABS Material Create end-use parts, functional prototypes, and manufacturing tools with real ABS material and Stratasys SR-30 soluble support material. 21 Onboard Sensors A network of 21 intelligent sensors embedded throughout the printer gives you full control while making material and print management easy and accessible. Wireless Printing & Monitoring Away from the office? Remotely print, monitor, and control your printer from anywhere in the world. 5 inch Colour Touchscreen Swipe, tap, print. With the built-in 5” full-color capacitive touchscreen display, receive up-to-the-second status of your current print job and navigate menus in the most intuitive way you already know—with your finger. 25 CAD File Types With over 25 supported native CAD file types, you can focus on your next design sprint rather than messy plugins and conversions.

UNCOMPROMISED LAYER ADHESION AND PART STRENGTH

Circulating 100°C Heated Chamber Control the temperature and quality of every layer - not just the first. While heated build plates are effective at reducing warping, METHOD X takes this further with full active heat immersion during the entire duration of the print..

METHOD X Applications

Consistent print results with a dimensional accuracy of ±0.2mm End-use Parts Get dimensionally accurate, production grade, real ABS end-use parts at a fraction of traditional manufacturing costs. The MakerBot METHOD X reduces costs and saves time for small production manufacturing runs. Benefits Real, Production-grade ABS provides part properties closer to injection molded parts. Dimensionally accurate parts that fit seamlessly as part of an assembly, such as sensor mounts for an electronics assembly. Print complex assembly parts with carve-outs, holes and large overhangs. Get end-use parts in hours instead of weeks at a fraction of the cost, with a 3D printer that just works.

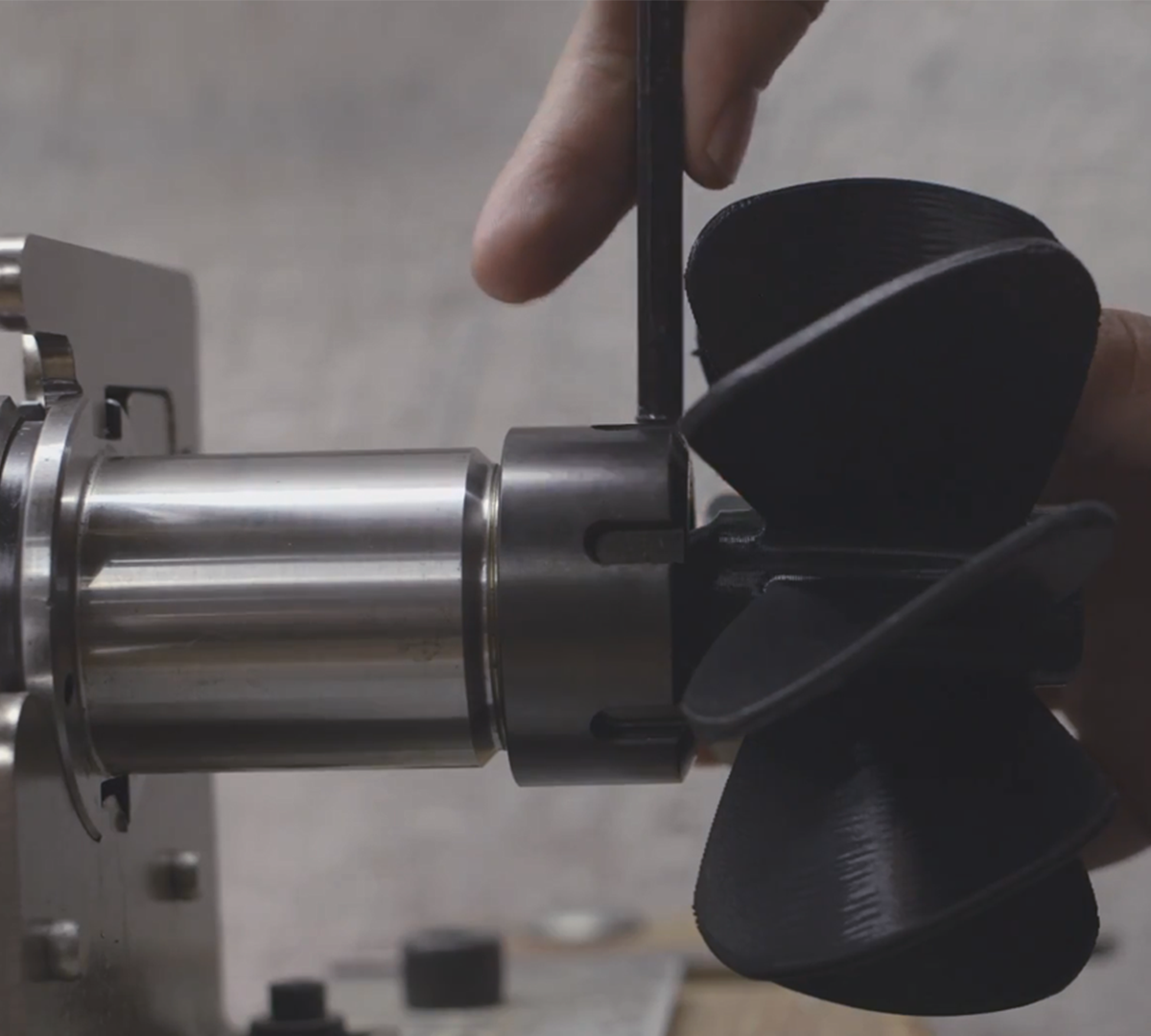

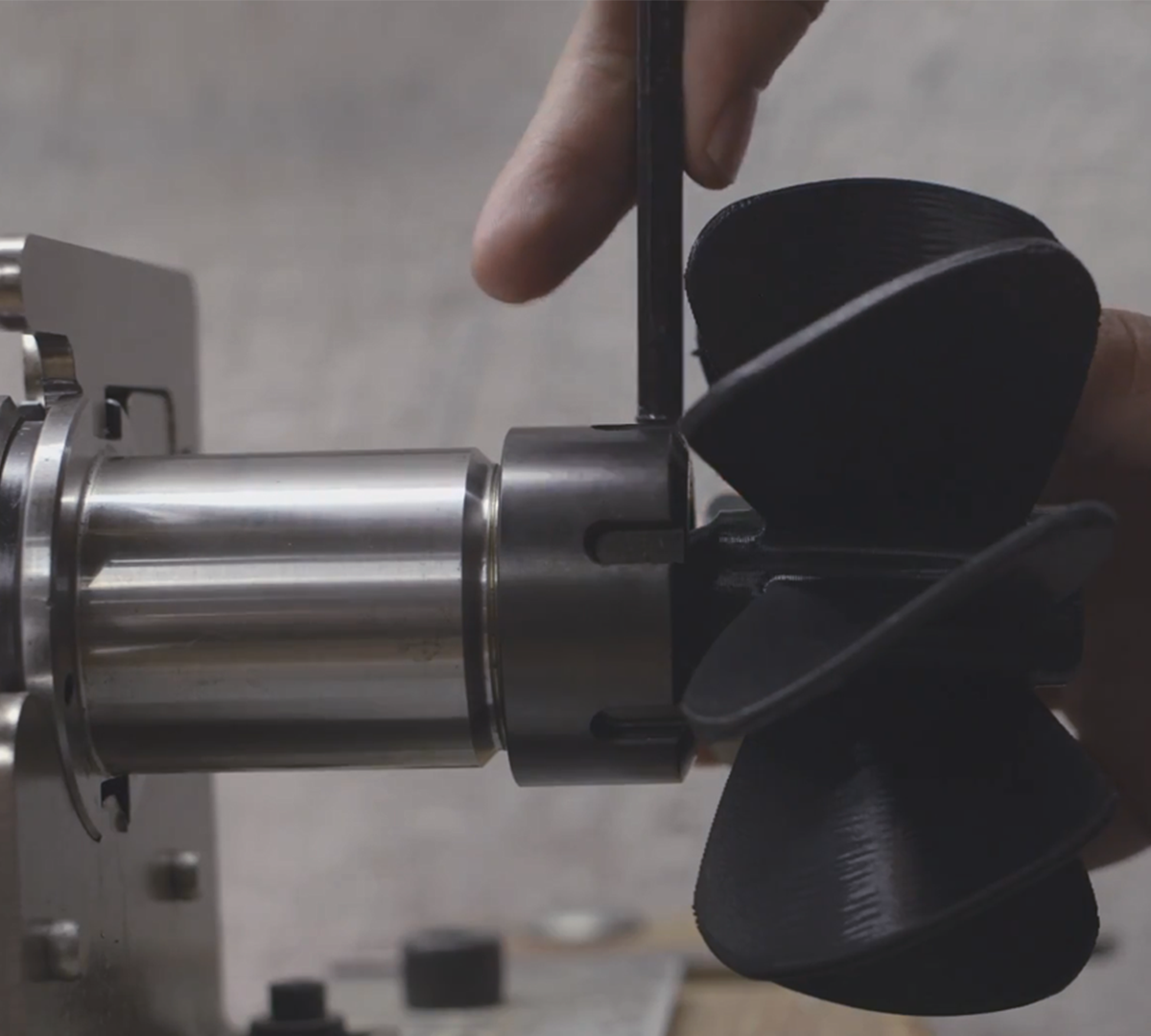

Functional Prototypes

Prototype with production-grade ABS to achieve part properties close to injection molded parts. Print dimensionally accurate assemblies and validate your designs to get your products to market faster—all at a fraction of industrial 3D printing costs. Benefits Dimensionally accurate parts that fit seamlessly as parts of an assembly, such as impeller assembly or electronics housings. Parts print with flat roofs, cylindricity, and superior vertical layer uniformity. Prototype with production-grade ABS to achieve part properties closer to injection molding. Complex assembly geometries like gears, threads, carve-outs, and large overhangs. Get fit and functional prototypes quickly with a 3D printer that just works. Functional Prototypes Prototype with production-grade ABS to achieve part properties close to injection molded parts. Print dimensionally accurate assemblies and validate your designs to get your products to market faster—all at a fraction of industrial 3D printing costs. Benefits Dimensionally accurate parts that fit seamlessly as parts of an assembly, such as impeller assembly or electronics housings. Parts print with flat roofs, cylindricity, and superior vertical layer uniformity. Prototype with production-grade ABS to achieve part properties closer to injection molding. Complex assembly geometries like gears, threads, carve-outs, and large overhangs. Get fit and functional prototypes quickly with a 3D printer that just works.

Manufacturing Tools

Create durable, real ABS parts for the production floor. Print dimensionally accurate jigs, fixtures, and end-effectors that fit seamlessly with existing components. Benefits Real, engineering-grade ABS that can withstand the harsh manufacturing environment and ensure long tool life. Dimensionally accurate parts that fit seamlessly with existing components, such as a robot arm. Parts print with flat roofs, cylindricity, and superior vertical layer uniformity. Soluble supports to print complex tool geometries with carve-outs, holes and large overhangs that are difficult or impossible to produce with traditional methods. Get tools in hours instead of weeks with a 3D printer that just works.

UNRESTRICTED GEOMETRIC FREEDOM

Disolvable Support System Superior surface finish and unrestricted geometric freedom are paramount to delivering high quality printed parts. Stratasys SR-30 ensures fast and effortless support removal without compromising part design or dimensional accuracy. Stratasys SR-30 soluble support material provides two key benefits: Unrestricted geometric freedom (large overhangs, cavities, etc.) Superior print quality and surface finish.

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| FEATURE | METHOD | METHOD X |

|---|---|---|

| Why? | Only low temp materials needed | ABS or other high temp materials are needed |

| Dimensional Accuracy | ±0.2mm (0.007in) | |

| Heated Build Chamber Temperature | 60°C | 100°C |

| Dual Performance Extruders | Model 1 Extruder - 900-0012A Support 2 Extruder-900-0013A | Model 1X Extruder - 900-0043A Support 2X Extruder-900-0044A Model 1 Extruder - 900-0012A Support 2 Extruder - 900-0013A |

| Power Requirements | 100 - 240 VAC, 50/ 60 Hz, 400 W max 3.9A -1.6A | 100 - 240 VAC, 50/ 60 Hz, 800 W max 8.1A- 3.4 A |

| Layer Resolution | 20-400 micron | |

| Build Volume | Single Extrusion 19 L x 19 W x 19.6 H cm / 7.5 x 7.5 x 7.75 Dual Extrusion 15.2 L x 19 W x 19.6 H cm / 6.0 x 7.5 x 7.75 in | |

| MakerBot Materials | Precision Materials: PLA, Tough, PVA Specialty Materials: PETG | Precision Materials: PLA, Tough, PVA, ABS, Stratasys® SR-30 Specialty Materials: PETG |

| Applications | Concept - Quick Prototypes - Fit Tests - Concept Iterations | Production - Manufacturing Tools - End-use Parts - Functional Prototypes |

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

Why MakerBot METHOD X?

aster and more precise printing than ever before with manufacturing features you need: Production-grade ABS Material Create end-use parts, functional prototypes, and manufacturing tools with real ABS material and Stratasys SR-30 soluble support material. 21 Onboard Sensors A network of 21 intelligent sensors embedded throughout the printer gives you full control while making material and print management easy and accessible. Wireless Printing & Monitoring Away from the office? Remotely print, monitor, and control your printer from anywhere in the world. 5 inch Colour Touchscreen Swipe, tap, print. With the built-in 5” full-color capacitive touchscreen display, receive up-to-the-second status of your current print job and navigate menus in the most intuitive way you already know—with your finger. 25 CAD File Types With over 25 supported native CAD file types, you can focus on your next design sprint rather than messy plugins and conversions.

UNCOMPROMISED LAYER ADHESION AND PART STRENGTH

Circulating 100°C Heated Chamber Control the temperature and quality of every layer - not just the first. While heated build plates are effective at reducing warping, METHOD X takes this further with full active heat immersion during the entire duration of the print..

METHOD X Applications

Consistent print results with a dimensional accuracy of ±0.2mm End-use Parts Get dimensionally accurate, production grade, real ABS end-use parts at a fraction of traditional manufacturing costs. The MakerBot METHOD X reduces costs and saves time for small production manufacturing runs. Benefits Real, Production-grade ABS provides part properties closer to injection molded parts. Dimensionally accurate parts that fit seamlessly as part of an assembly, such as sensor mounts for an electronics assembly. Print complex assembly parts with carve-outs, holes and large overhangs. Get end-use parts in hours instead of weeks at a fraction of the cost, with a 3D printer that just works.

Functional Prototypes

Prototype with production-grade ABS to achieve part properties close to injection molded parts. Print dimensionally accurate assemblies and validate your designs to get your products to market faster—all at a fraction of industrial 3D printing costs. Benefits Dimensionally accurate parts that fit seamlessly as parts of an assembly, such as impeller assembly or electronics housings. Parts print with flat roofs, cylindricity, and superior vertical layer uniformity. Prototype with production-grade ABS to achieve part properties closer to injection molding. Complex assembly geometries like gears, threads, carve-outs, and large overhangs. Get fit and functional prototypes quickly with a 3D printer that just works. Functional Prototypes Prototype with production-grade ABS to achieve part properties close to injection molded parts. Print dimensionally accurate assemblies and validate your designs to get your products to market faster—all at a fraction of industrial 3D printing costs. Benefits Dimensionally accurate parts that fit seamlessly as parts of an assembly, such as impeller assembly or electronics housings. Parts print with flat roofs, cylindricity, and superior vertical layer uniformity. Prototype with production-grade ABS to achieve part properties closer to injection molding. Complex assembly geometries like gears, threads, carve-outs, and large overhangs. Get fit and functional prototypes quickly with a 3D printer that just works.

Manufacturing Tools

Create durable, real ABS parts for the production floor. Print dimensionally accurate jigs, fixtures, and end-effectors that fit seamlessly with existing components. Benefits Real, engineering-grade ABS that can withstand the harsh manufacturing environment and ensure long tool life. Dimensionally accurate parts that fit seamlessly with existing components, such as a robot arm. Parts print with flat roofs, cylindricity, and superior vertical layer uniformity. Soluble supports to print complex tool geometries with carve-outs, holes and large overhangs that are difficult or impossible to produce with traditional methods. Get tools in hours instead of weeks with a 3D printer that just works.

UNRESTRICTED GEOMETRIC FREEDOM

Disolvable Support System Superior surface finish and unrestricted geometric freedom are paramount to delivering high quality printed parts. Stratasys SR-30 ensures fast and effortless support removal without compromising part design or dimensional accuracy. Stratasys SR-30 soluble support material provides two key benefits: Unrestricted geometric freedom (large overhangs, cavities, etc.) Superior print quality and surface finish.

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

| FEATURE | METHOD | METHOD X |

|---|---|---|

| Why? | Only low temp materials needed | ABS or other high temp materials are needed |

| Dimensional Accuracy | ±0.2mm (0.007in) | |

| Heated Build Chamber Temperature | 60°C | 100°C |

| Dual Performance Extruders | Model 1 Extruder - 900-0012A Support 2 Extruder-900-0013A | Model 1X Extruder - 900-0043A Support 2X Extruder-900-0044A Model 1 Extruder - 900-0012A Support 2 Extruder - 900-0013A |

| Power Requirements | 100 - 240 VAC, 50/ 60 Hz, 400 W max 3.9A -1.6A | 100 - 240 VAC, 50/ 60 Hz, 800 W max 8.1A- 3.4 A |

| Layer Resolution | 20-400 micron | |

| Build Volume | Single Extrusion 19 L x 19 W x 19.6 H cm / 7.5 x 7.5 x 7.75 Dual Extrusion 15.2 L x 19 W x 19.6 H cm / 6.0 x 7.5 x 7.75 in | |

| MakerBot Materials | Precision Materials: PLA, Tough, PVA Specialty Materials: PETG | Precision Materials: PLA, Tough, PVA, ABS, Stratasys® SR-30 Specialty Materials: PETG |

| Applications | Concept - Quick Prototypes - Fit Tests - Concept Iterations | Production - Manufacturing Tools - End-use Parts - Functional Prototypes |

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.